Created in 1953 in the Lyon area , our company, which specialises in the transformation and injection moulding of thermoplastic resins, has 3 production sites:

-

-

-

- Arindis in Saint-Genis-Laval (69)

- Arindis in Nantoin (38)

- Plastitec in Nowa Ruda (Poland).

-

-

Our job allows you to optimize the design of your products, to assist in the production of tooling, to produce parts and finishing operations in series.

Our solutions provide a global response to your needs in various fields: electrical equipment, home automation, security, medical, fluid distribution, automotive, etc…

Production Capacity

- Plastic injection: 40 robotic injection moulding machines from 10 to 700T.

- Processing and supply of engineering plastics, mineral filled and fibreglass or unfilled: PP, PE, ABS, PA, PAAR, PBT, PMMA, POM, PPO, PC, PPE, PEEK, PEI, PPS…

- Control of the injection process with the eDart system.

- 3D printing: powder sintering, stereolithography, wire deposition .

- Decoration: pad printing, laser marking, painting.

- Assembly: ultrasonic welding, special tools, Cobot collaborative robotics.

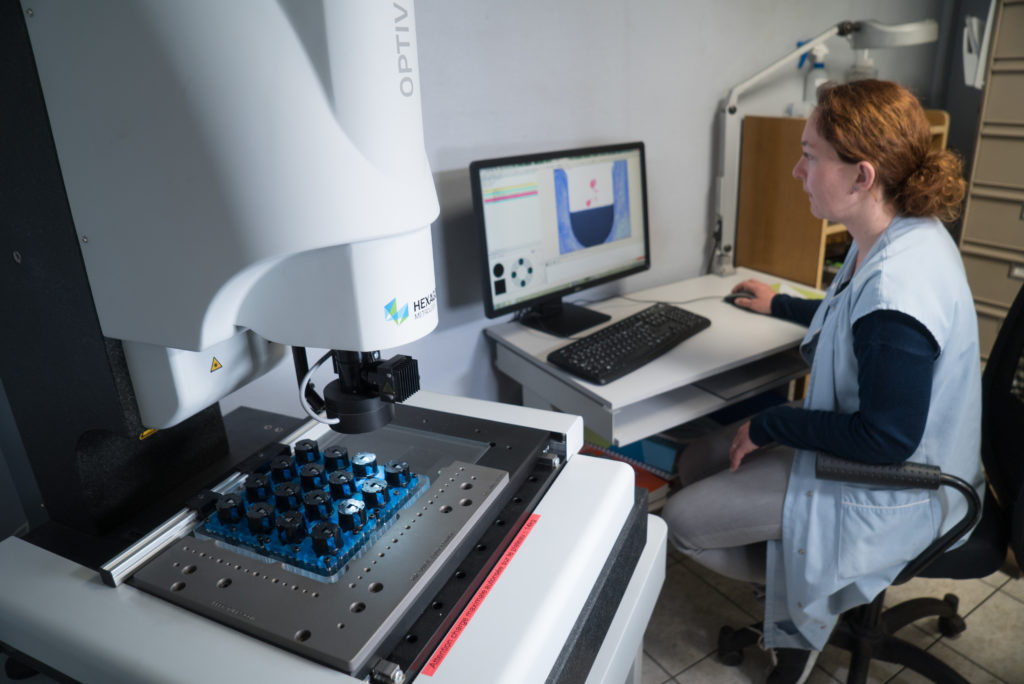

- ISO 9001 quality system, 3D contact and optical inspection, roughness measurements, leakage control and other specific control devices.

Capacité d’étude

- Product design: assistance in the design of your products from the prototype stage to series production, advice in a wide choice of processed materials (PP, ABS, PC, PA, PBT, PEI, PAAR, PEEK, …) according to functional requirements.

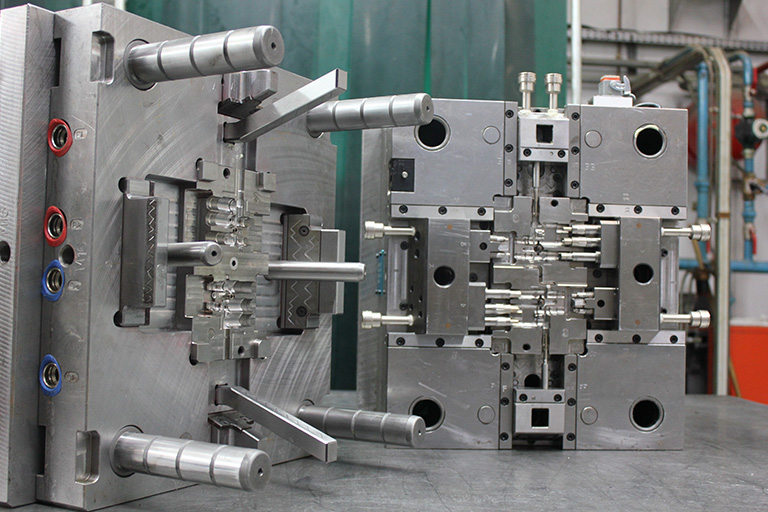

- Tooling design: technical expertise in tooling to guarantee the stability of the process and the final quality of the moulded parts.

- Industrialization of additional operations: we design and manufacture the special tools necessary for the assembly or control of sub-assemblies.

Engagement Qualité

Our French factories Arindis and our Polish factory Plastitec have been ISO9001 certified since 2018 . In order to increase our customers’ satisfaction, we guarantee them a personalized attention and advice associated with a very strong involvement of all our staff.

We meet the requirements relating to the essential components of the quality approach:

- Management’s responsibility: requirement for initial involvement of management as the first permanent actor in the process.

- Quality System: requirement for the construction of a system, guaranteeing overall consistency and in particular the capitalisation of achievements.

- Processes: requirement to identify and manage all processes contributing to the satisfaction of our customers.

- Continuous improvement: requirement to commit to effective improvement actions, including measuring and recording performance in all relevant areas and at all relevant levels.